Research

New manufacturing methods such as 3D printing have enabled an unprecedented degree of control over the properties of materials. This has the potential to revolutionize materials properties and to thereby greatly expand the design space available to engineers. How can we leverage these tools to produce materials and structures with unprecedented engineered capabilities?

At the Architected Materials Laboratory we explore this question, with our work organized into three major Thrusts: (1) Geometric control of nonlinear behavior; (2) 3D-printable composites and responsive materials; and (3) Mechanical logic and autonomous materials (obtained by combining Thrusts 1 and 2).

Further details about these efforts are given below.

(1) GEOMETRIC CONTROL OF NONLINEAR BEHAVIOR

Traditional manufacturing is primarily concerned with the external shape of parts (as controlled via casting, machining, etc.). 3D printers allow construction of parts with nearly arbitrary internal structure. This new capability opens up vast new design spaces. How can we use internal geometry to impart new functionality to materials, e.g., to control how stress waves propagate through the material during impact, or to reprogram the shape or properties of a metamaterial? Our work in this area has largely focused on the design, realization, and experimental, numerical, and theoretical characterization of nonlinear behaviors induced by simple geometric mechanisms.

(1.1) Geometry and wave propagation

Minor variations in geometry are known to have a large influence on dynamic properties such as wave propagation. Many previous studies have explored how this affects propagation of small-amplitude linear elastic waves, e.g., leading to band gaps. In our group we are interested in high-amplitude loading, such as that experienced during impact. The internal geometry of the medium has an extremely large effect on the response during such nonlinear loading events, leading to a variety of rich phenomena, such as the propagation of elastic vector solitons, controlled focusing or spreading of impact energy, the propagation of transition waves, and conversion of impactor kinetic energy into stored elastic energy (and “phase changes”) within the medium.

Minor variations in geometry are known to have a large influence on dynamic properties such as wave propagation. Many previous studies have explored how this affects propagation of small-amplitude linear elastic waves, e.g., leading to band gaps. In our group we are interested in high-amplitude loading, such as that experienced during impact. The internal geometry of the medium has an extremely large effect on the response during such nonlinear loading events, leading to a variety of rich phenomena, such as the propagation of elastic vector solitons, controlled focusing or spreading of impact energy, the propagation of transition waves, and conversion of impactor kinetic energy into stored elastic energy (and “phase changes”) within the medium.

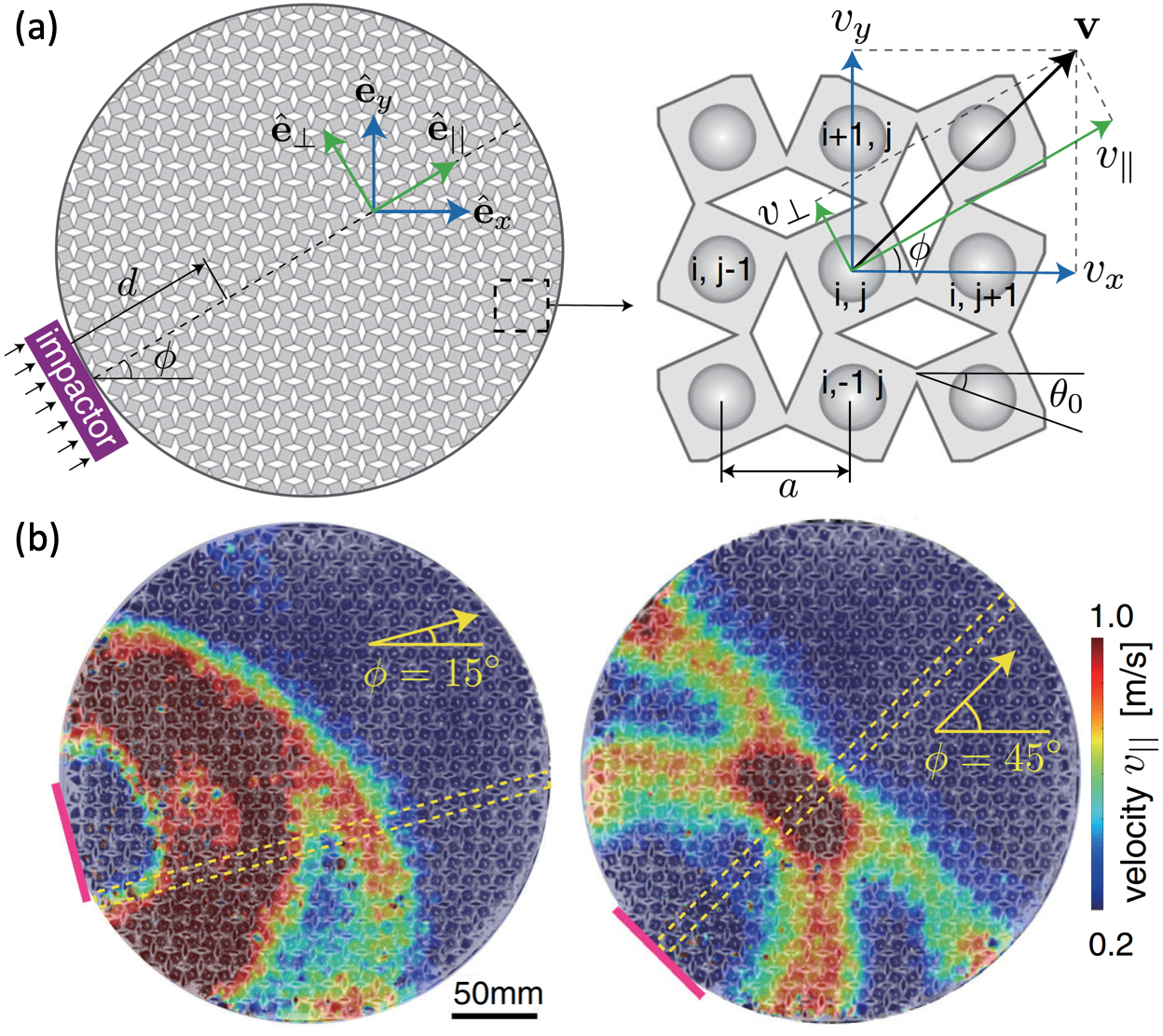

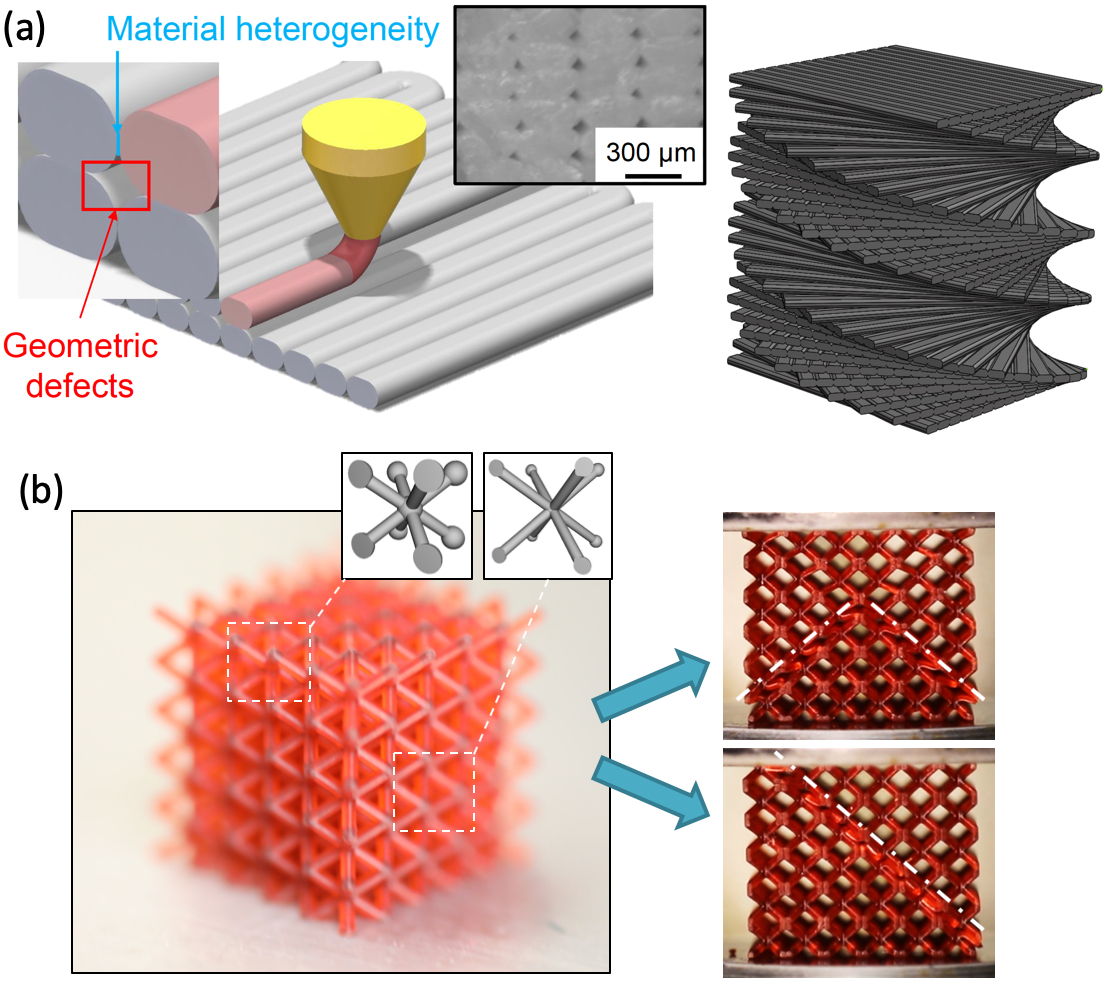

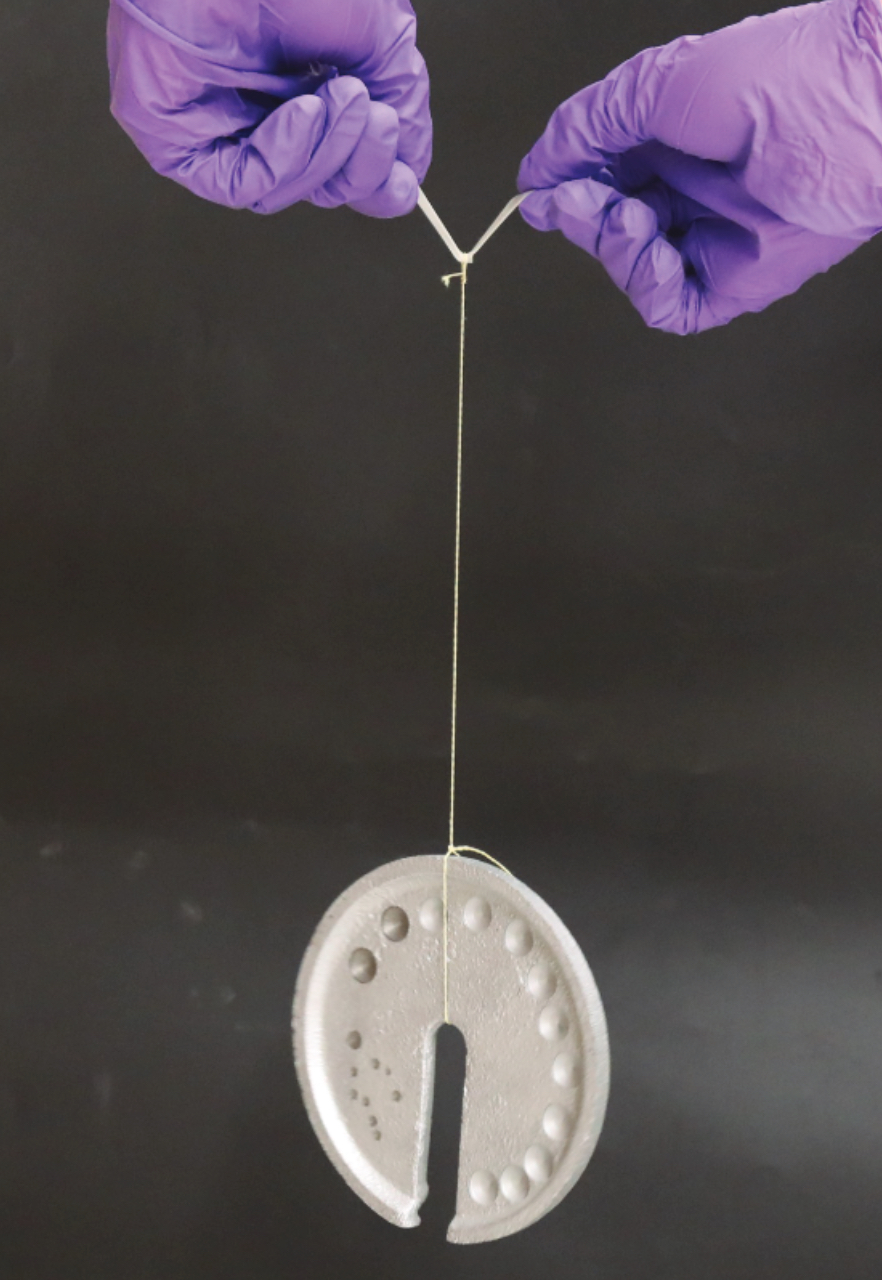

The figure at left shows an example mechanical metamaterial composed of a system of rotating squares connected at their vertices. We 3D print such structures using direct ink writing. In this case, the material is a conventional silicone (PDMS). Impacting the structure on the edge can cause a vector soliton to propagate through the structure. Depending on the impact angle, the impulse may split into two soliton modes with distinct wave speeds.

Additional nonlinear dynamic effects can be realized by including magnets in the squares. This introduces multistability to the system, allowing the squares to take on different stable configurations. Each stable angle is analogous to a “phase”. By impacting the structure, a phase change can be induced, which can propagate through the rest of the structure via a transition wave. In addition to the fundamental interest in this nonlinear behavior, it is also constitutes a strategy for producing global shape changes in response to local forces. These controllable shape changes are relevant in a large variety of applications, including robotics, medical devices, and aerospace.

Additional nonlinear dynamic effects can be realized by including magnets in the squares. This introduces multistability to the system, allowing the squares to take on different stable configurations. Each stable angle is analogous to a “phase”. By impacting the structure, a phase change can be induced, which can propagate through the rest of the structure via a transition wave. In addition to the fundamental interest in this nonlinear behavior, it is also constitutes a strategy for producing global shape changes in response to local forces. These controllable shape changes are relevant in a large variety of applications, including robotics, medical devices, and aerospace.

Finally, we have also begun to look at how multiple nonlinear waves can interact within mulistable media to produce complex responses. For example, the figures below show examples of collisions of vector solitons in 1D and 2D systems. If certain energy and kinematic criteria are met, the collisions of these pulses induce a phase transition at the site of the collision. The new phase can subsequently grow throughout the medium in the form of transition waves. From a fundamental perspective, these collisions are fascinating: the kinetic energy of the colliding vector solitons is deposited as strain energy at the site of the collision. From a more practical perspective, understanding how nonlinear waves interact in mechanical metamaterials could lead to new strategies for dealing with impact loading in structures, such as control of stress waves and energy when vehicles collide.

|

|

|

Collision of two vector solitons in a 1D multistable mechanical metamaterial, inducing a phase change in the metamaterial.

|

Collision of two vector solitons in a 2D multistable mechanical metamaterial, inducing a phase change in the metamaterial.

|

This work has been supported by the National Science Foundation and the Army Research Office.

Some of our recent work related to this topic:

- W. Jiao, H. Shu, H. Yasuda, V. Tournat, J. R. Raney, “Dynamic nucleation and growth of phase transitions in a 2D mechanical metamaterial,” in preparation 2022.

- H. Yasuda, H. Shu, W. Jiao, V. Tournat, J. R. Raney, “Nucleation of transition waves via collisions of elastic vector solitons,” in review 2022.

- H. Yasuda, E. G. Charalampidis, P. K. Purohit, P. G. Kevrekidis, J. R. Raney, “Wave manipulation using a bistable chain with reversible impurities,” Phys. Rev. E 2021; 104:054209.

- H. Yasuda, L. M. Korpas, J. R. Raney, “Transition waves and formation of domain walls in multistable mechanical metamaterials,” Phys. Rev. Applied 2020;13:054067.

- C. Mo, J. Singh, J. R. Raney, P. K. Purohit, “Cnoidal wave propagation in an elastic metamaterial,” Phys. Rev. E 2019;100:013001.

- B. Deng, C. Mo, V. Tournat, K. Bertoldi, J. R. Raney, “Focusing and mode separation of elastic vector solitons in a 2D soft mechanical metamaterial,” Phys. Rev. Lett 2019;123:024101.

(1.2) Geometry and fracture

3D printing and other advanced manufacturing techniques have enabled unprecedented control of geometry. Origami, beams, and systems of connected polygons are all examples of structures for which the mechanical response can be drastically changed by even small changes to geometry. While our primary focus in this research area has been to understand the role of geometry on nonlinear dynamic phenomena, as described above, we are exploring how subtle variations to the internal geometry of 3D printed structures can lead to drastic changes to the fracture behavior. Inpsired by structures in nature, we have been developing bioinspired design algorithms that produce lightweight structures that internally divert and/or arrest cracks, improving the resilience of the structure even after significant damage has occurred.

3D printing and other advanced manufacturing techniques have enabled unprecedented control of geometry. Origami, beams, and systems of connected polygons are all examples of structures for which the mechanical response can be drastically changed by even small changes to geometry. While our primary focus in this research area has been to understand the role of geometry on nonlinear dynamic phenomena, as described above, we are exploring how subtle variations to the internal geometry of 3D printed structures can lead to drastic changes to the fracture behavior. Inpsired by structures in nature, we have been developing bioinspired design algorithms that produce lightweight structures that internally divert and/or arrest cracks, improving the resilience of the structure even after significant damage has occurred.

This work has been supported by the National Science Foundation.

Some of our recent work related to this topic:

- C. Mo, P. Perdikaris, J. R. Raney, “Accelerated design of architected solids with multi-fidelity Bayesian optimization,” in review 2022.

- C. Mo, J. R. Raney, “Spatial programming of defect distributions to enhance material failure characteristics,” Extreme Mechanics Letters 2019;100598.

(2) 3D-PRINTABLE COMPOSITES AND RESPONSIVE MATERIALS

While 3D printers are excellent for exploring novel structural designs, 3D-printed materials often have poor mechanical properties or poorly understood microstructures. Our group seeks to develop improved composites and responsive materials for 3D printers. A very common problem with 3D-printed materials (both soft materials and structural materials) is their tendency to fail prematurely, limiting their use in industry. We are particularly interested in understanding how 3D-printed materials deform and fail, with the goal of improving their robustness and longevity. As part of this, we seek to leverage the unique aspects of additive processes to impart multiscale structure, similar to that observed in natural materials.

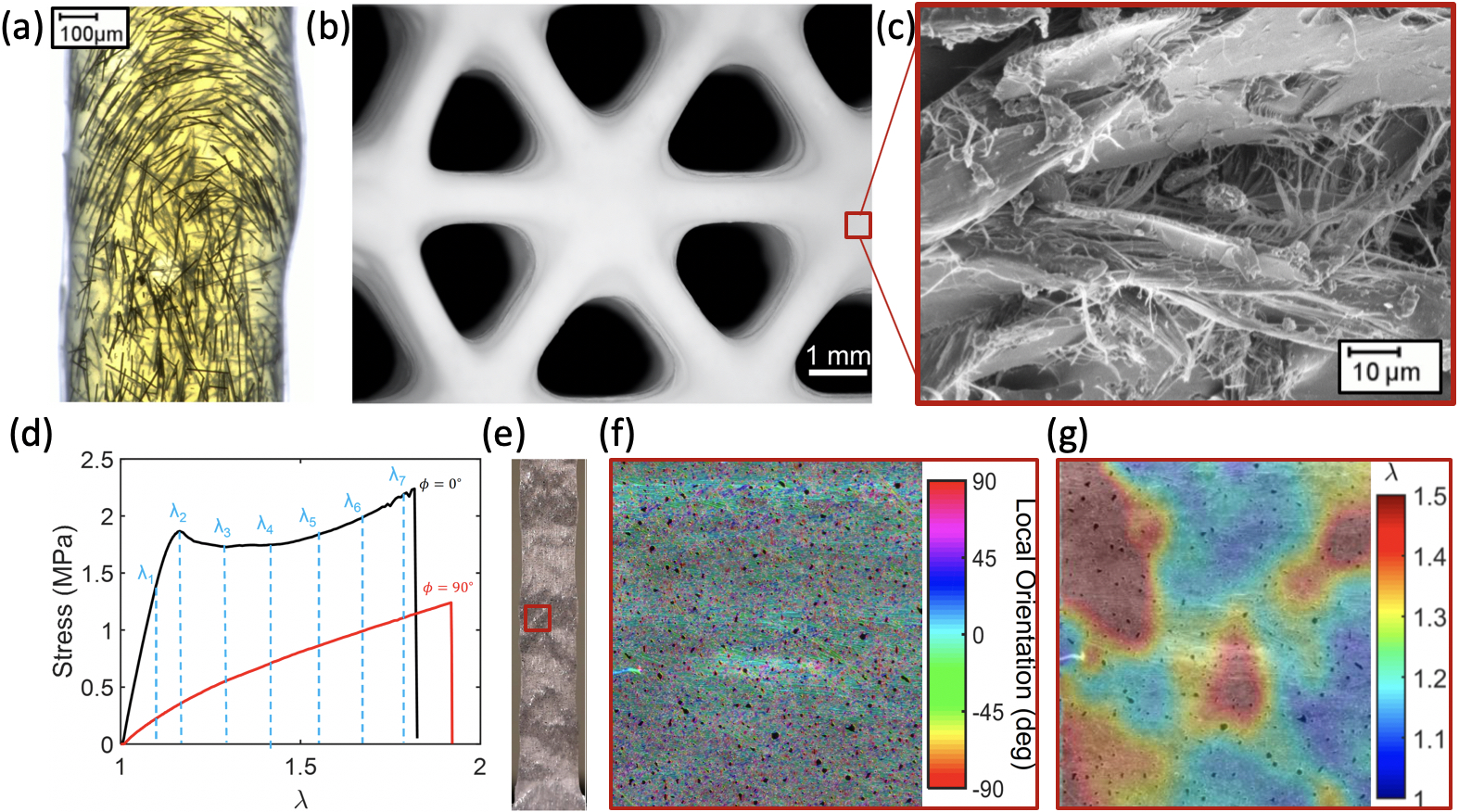

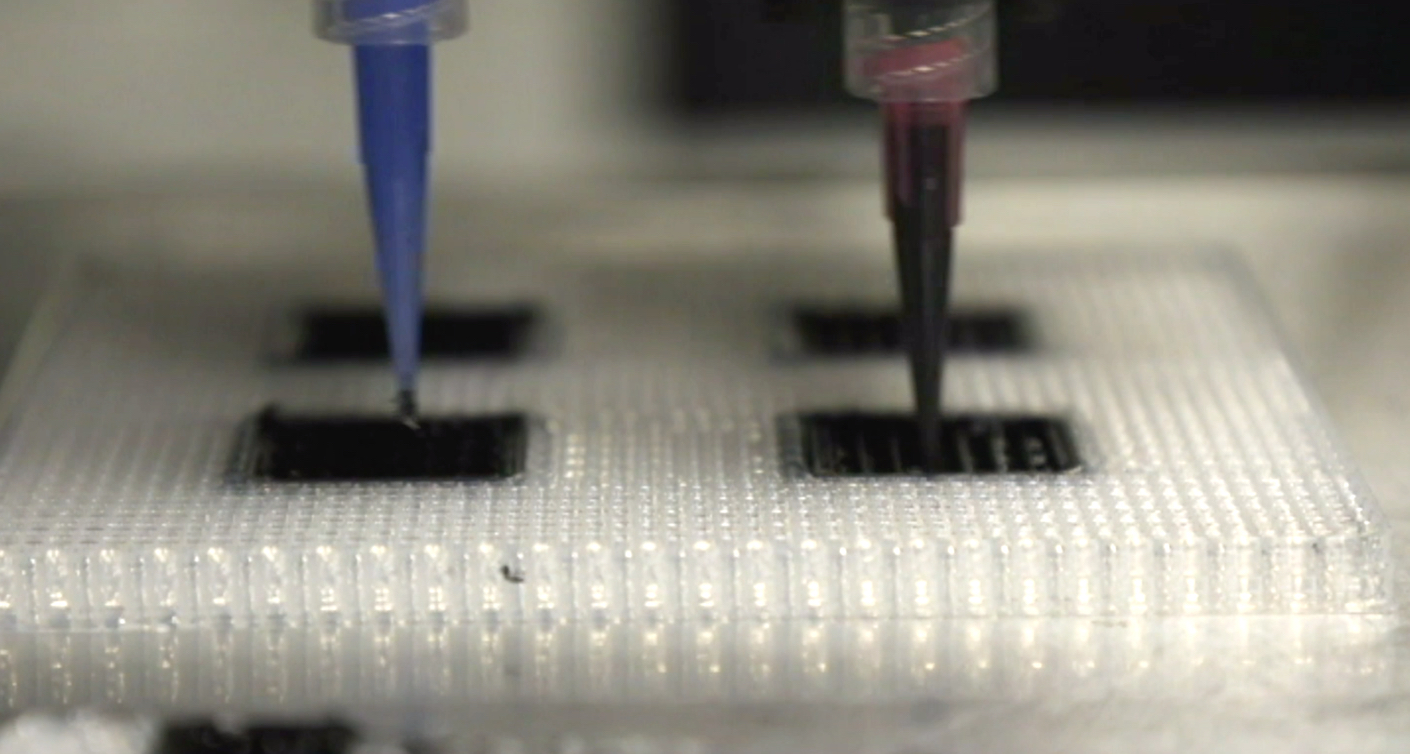

Natural lightweight materials such as wood, bone, and shells consist of complicated multiscale features, such as heterogeneous compositions and spatially-varying fiber alignments. By careful material design and simultaneous hardware development, we have developed 3D-printable, fiber-reinforced composite inks. By designing novel 3D printing nozzles we are able to control fiber alignment and compositional heterogeneity to achieve enhanced mechanical performance, following approaches and designs inspired by nature.

A few examples of our work in this area are shown in the above image. Panel (a) shows precise control of fiber alignment in a carbon fiber-epoxy composite. This is achieved by using a rotating nozzle that can impart variable rotational shear to the material as it is printed. Panels (b-c) show a printable amylopectin-cotton fiber composite. The amylopectin comes from common “sticky rice”. The composite has mechanical properties comparable to common 3D-printed thermoplastics such as PLA, but is non-toxic, renewable, sustainable, and inexpensive, made entirely from natural materials.

Materials with complex microstructures, like those shown above, often have very complex deformation and failure characteristics. Soft composites are still more complex. Ultimately, to make 3D-printable composites with better mechanical properties, it is necessary to understand how the microstructure influences the properties we care about. To help understand this, we use in situ digital image correlation. These tests provide data on how the microstructure locally deforms while simultaneously providing macroscale mechanical properties such as stiffness, toughness, and strength. Panel (d-g) provides an example of this for a highly-stretchable silicone-glass fiber composite. This multiscale experimental data provides a fiber alignment map and local stress-stretch field (the latter obtained via digital image correlation). Using these tools, we have recently developed new aorta-inspired and extremely tough 3D-printable soft composites with failure properties superior to that of skin.

|

|

Our group is also interested in 3D-printable responsive and/or multifunctional composites that deform or change properties in response to their environment. This includes liquid crystal elastomers, hydrogels, and soft conductive composites.

This work has been supported by the Air Force Office of Scientific Research, 3M, and the National Science Foundation.

Some of our recent work related to this topic:

- C. Mo, R. Yin, J. R. Raney, “Direct ink writing of tough, stretchable silicone composites,” Soft Matter in press 2022. DOI: 10.1039/D2SM00923D

- C. Mo, H. Long, J. R. Raney, “Tough, aorta-inspired soft composites,” Proceedings of the National Academy of Sciences 2022; 119(28):e2123497119.

- L. M. Korpas, R. Yin, H. Yasuda, J. R. Raney, “Temperature-responsive multistable metamaterials,” ACS Applied Materials & Interfaces 2021;13(26):31163-31170.

- C. Mo, Y. Jiang, J. R. Raney, “Microstructural evolution and failure in short fiber soft composites: Experiments and modeling,” Journal of the Mechanics and Physics of Solids 2020;141:103973.

- Y. Jiang, J. R. Raney, “3D printing of amylopectin-based natural fiber composites,” Adv. Mater. Technol. 2019;1900521.

(3) MECHANICAL LOGIC AND AUTONOMOUS MATERIALS

Is it possible to imagine intelligence, or information processing, as a material property, just as stiffness or strength is?

For example, consider the Venus flytrap, which, upon partially closing around potential prey, waits to determine whether or not to begin digestion based on the size and movement of the object. Obtaining this level of complexity in synthetic systems usually requires familiar combinations of microprocessors, sensors, actuators, etc. In this work, we seek to “embody” some degree of decision-making ability and responsiveness (i.e., sensing, control logic, and actuation) into multi-material, 3D-printed structures rather than relying on mechatronic systems.

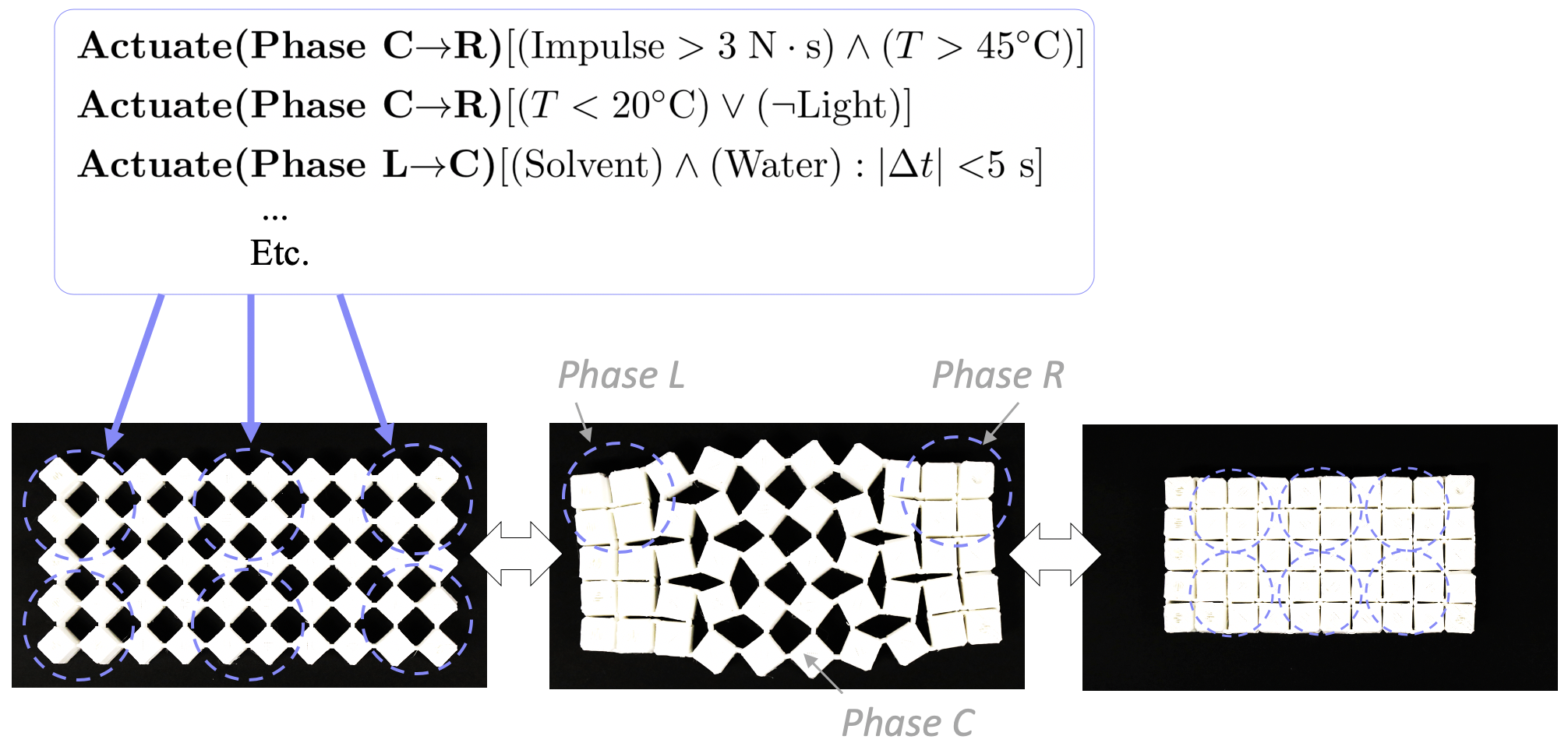

This research thrust derives from both of the previous thrusts described above: In Thrust 1, described above, we design nonlinear mechanisms that undergo large changes to their properties in response to even slight changes to their parameters (e.g., the thickness of the hinges between the squares). In Thrust 2, we develop 3D-printable composites that deform in response to their environment (e.g., changes in heat, moisture, or mechanical forces). By coupling these responsive composites with nonlinear mechanisms, we engineer systems that can sense, decide, and move in response to their environment. The multimaterial, responsive mechanical metamaterials blur the distinction between “materials” and “robots”.

Using these principles, for example, one could design a deployable structure that only opens if precise conditions are met (e.g., “change shape if and only if the temperature is between 40-60 degrees Celsius and the structure has been exposed to humidity above 80% for a period of at least 3 minutes”). Behaviors such as this can be programmed solely as a function of material composition and local geometry, enabling some degree of autonomous function without the use of any electronics.

This work has been supported by the Army Research Office, Air Force Office of Scientific Research, and DARPA.

Some of our recent work related to this topic:

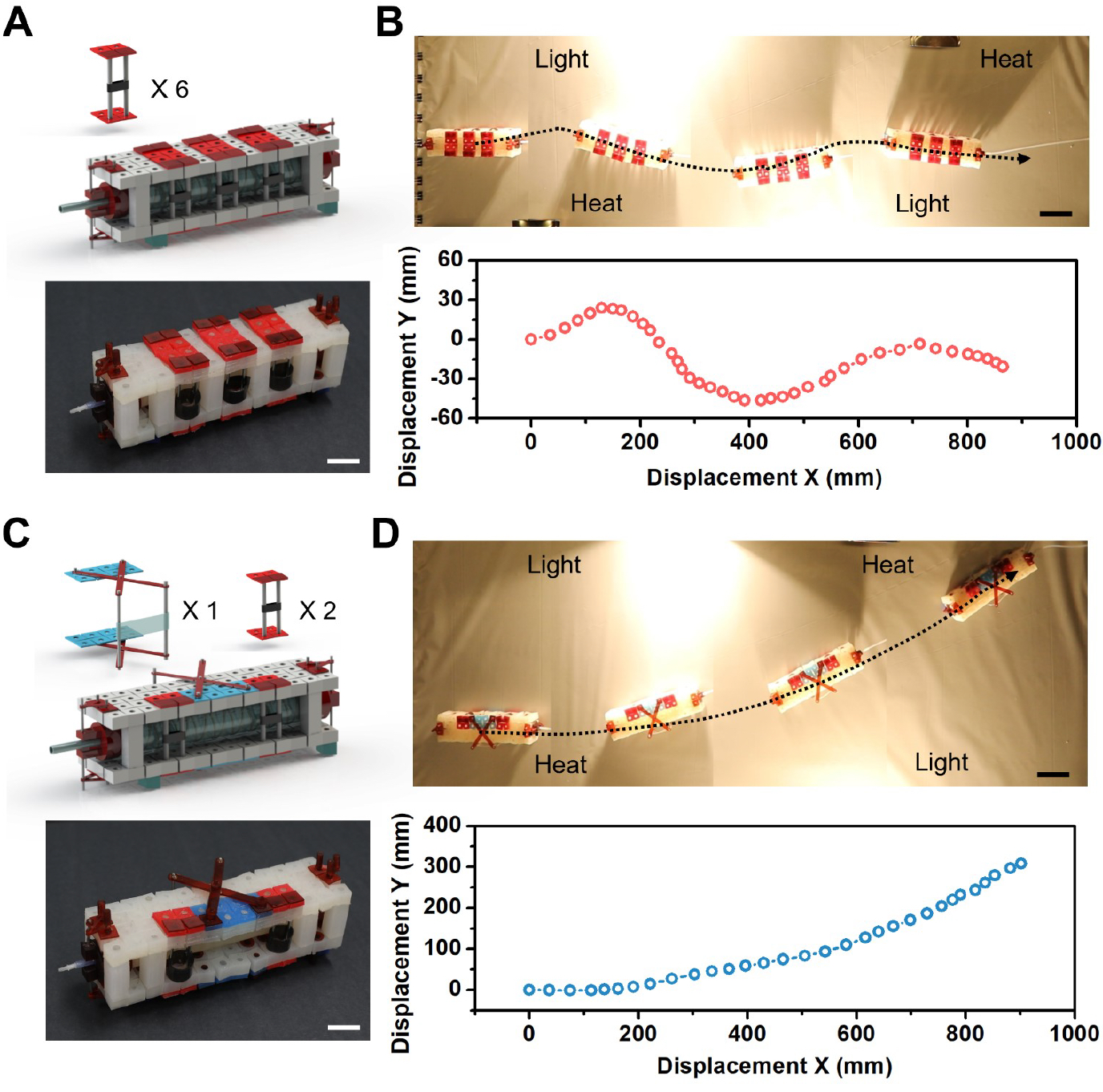

- Q. He, R. Yin, Y. Hua, W. Jiao, C. Mo, H. Shu, J. R. Raney, “A modular, embodied control strategy for electronics-free soft robots,” in review 2022.

- H. Yasuda, K. Johnson, V. Arroyos, K. Yamaguchi, J. R. Raney, J. Yang, “Leaf-like origami with bistability for self-adaptive grasping motion,” Soft Robotics 2022; (published online, DOI: 10.1089/soro.2021.0008).

- H. Yasuda, P. R. Buskohl, A. Gillman, T. D. Murphey, S. Stepney, R. A. Vaia, J. R. Raney, “Mechanical computing,” Nature 2021; 598:39-48.

- L. M. Korpas, R. Yin, H. Yasuda, J. R. Raney, “Temperature-responsive multistable metamaterials,” ACS Applied Materials & Interfaces 2021;13(26):31163-31170.

- Y. Jiang, L. M. Korpas, J. R. Raney, “Bifurcation-based embodied logic and autonomous actuation,” Nature Communications 2019;10:128.